Make Smarter, More Informed WHS Decisions

Whether you’re diligent with work health and safety audits, or do them reluctantly, the best decisions you make are always informed ones – rooted in facts and experience. That’s what a WHS audit provides. Done right, an audit helps you meet your WHS compliance obligations and, just as importantly, uncovers opportunities to optimise performance at every level of your organisation.

What WHS Audits Can We Do?

We offer various types of workplace safety audits in Perth and beyond, from process and functional audits to management system audits and high-risk audits for any industry or business stream. All led by subject-matter experts (no one-size-fits-all, audit-by-numbers solutions here).

Our safety audit consultants will clearly identify issues and, crucially, provide effective solutions, ensuring your WHS documentation and systems are effective and pass muster, compliance-wise.

Management System Audits

Reaching horizontally, organisation-wide, our environmental and safety management system audits examine your WHS policies and procedures and are typically assessed against the following standards:

WHS Compliance Audits

- WHS (General) Regulation Audit

- WHS (Mining) Regulation Audit

- Principal Mining Hazard Management Audit

- Mine Safety Management System Audit

- WorkSafe Plan Assessment Certification

ISO Audits

- ISO 45001 Occupational Health and Safety (OHS)

- ISO 45003 Management of Psychological Risk

- ISO 14001 Environmental Management Systems

- ISO 9001 Quality Assurance

- AS/NZS 4801 & OHSAS 18001 OHS Management System

Safety Process and Function Audits

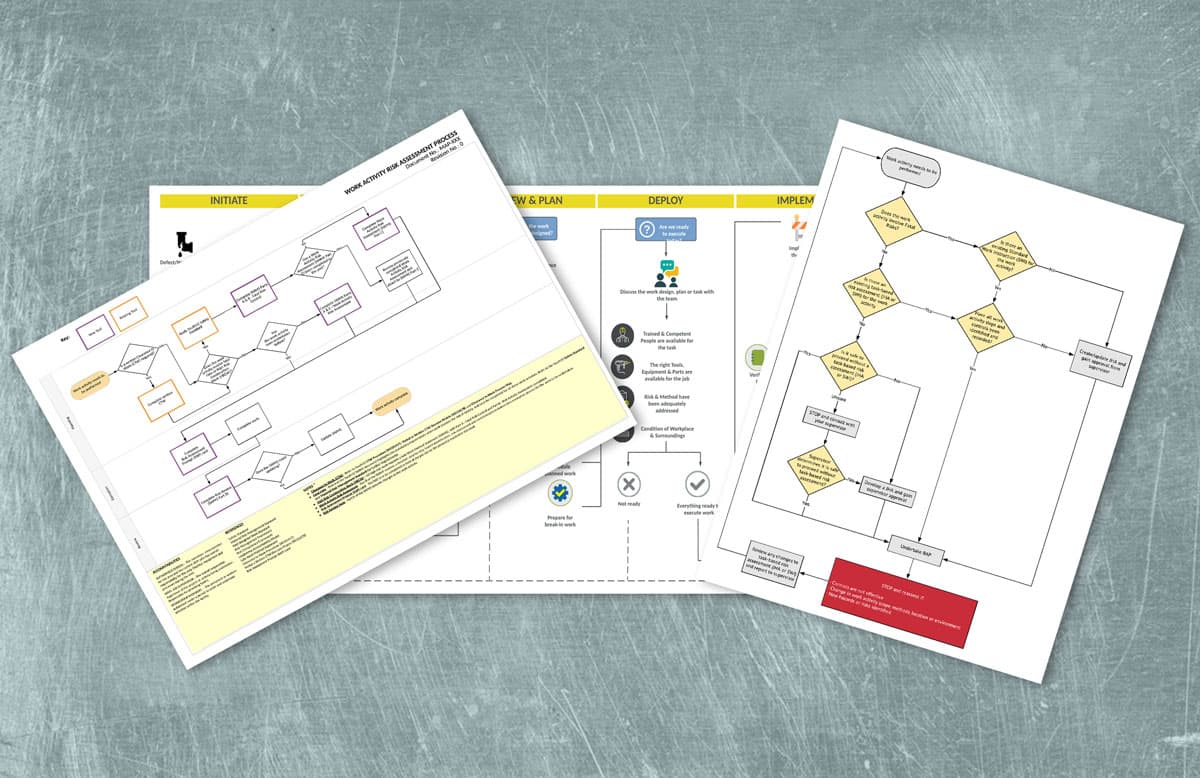

Our safety process and function audits thoroughly examine specific activities from top to bottom within your organisation’s vertical silos. These audits can take many forms, including:

- Management Systems Audit

- Contractor Management Audit

- Emergency Management Audit

- Confined Space Audit

- Working at Height Audit

- Permit to Work Audit

- Electrical Safety Audit

- Ergonomics Audit

- And more

By scrutinising these areas, we ensure that each aspect of your operations is safe, effective, and compliant.

How do we do it? Objectively.

| PLAN | DO | REVIEW | ||

| SCOPING MEETING | DESKTOP EVALUATION | STAKEHOLDER CONSULTATION | ON-SITE ASSESSMENT | ANALYSIS AND REPORT |

Project Spotlight: Alcoa Australia

Learn how we assist Alcoa with audit services to monitor contractor HSEQ performance (lead and lag indicator monitoring) across Alcoa Australia’s sites. Visit Case Study.

Ready to Talk About Workplace Safety Audits?

Take proactive steps now to optimise your safety standards, protect your staff, and boost overall performance. Contact our friendly team in Perth today on 1300 414 313 to schedule your safety audit and start creating a safer, more efficient workplace.