It’s the age-old problem: one minute you’re lifting loads or rotating right and left, the next you’re clutching your wrist or supporting your lower back.

Sound familiar? If so, you’re one of the 6.9 million Australians affected by a musculoskeletal condition.

What are work-related musculoskeletal disorders?

Musculoskeletal disorders encompass a wide range of inflammatory and degenerative conditions affecting the muscles, tendons, ligaments, joints, peripheral nerves and supporting blood vessels (Punnett & Wegman, 2004).

They can strike suddenly or develop over time, with the lower back, neck, shoulder, forearm and hand most commonly affected.

From the perspective of physical loading, several factors have been associated with WMSD’s, including repetitive motion, excessive force, awkward or sustained postures, as well as prolonged sitting and standing (Da Costa et al. 2010). So it’s no surprise that musculoskeletal conditions are often triggered by our jobs.

Work-related musculoskeletal disorders (WMSD) are the leading health and safety issue in Australia, impacting the quality of life of millions of people and their families.

WMSD are not caused by crushing, entrapment or cutting from operating equipment, they’re in an injury class of their own.

As well as affecting the individual, WMSD have a ripple effect of impacting colleagues and employers. This of course all comes at a price, with Safe Work Australia reporting an economic cost over $24 billion dollars in 2012-13.

Who is at risk of developing a WMSD?

A work-related musculoskeletal injury can creep into any occupation, but they are far more common in roles involving heavy loads and repetitive motions. Safe Work Australia also reported that the health and social services industry topped the WMSD list, followed by manufacturing, then construction.

In addition to this, many jobs involving driving result in a considerable amount of time sitting with an awkward posture. Couple this with manual handling in between driving stints and frequently turning the head and neck, and the spine is under serious strain.

Moreover, a variety of vibrations when frequently driving across poor asphalt and cobble, as well as traversing potholes and ditches can create sudden jolting or jerking events. These movements can create very sudden and rapid vertical accelerations.

Over time, all of this creates a very strong demand on the trunk and stabiliser muscles, and can cause fatigue over time.

Finally, our ageing demographic may expose older workers to an even greater risk of developing chronic musculoskeletal disorders. This demonstrates a clear requirement for companies to effectively target the factors contributing to the mechanisms of developing injuries.

How can we prevent work-related musculoskeletal disorders?

Work related injuries are often complex and require a systematic approach to mitigate the risks of sustaining them.

1. Understand physiological and psychosocial factors

Physiological and psychosocial factors play an important role in WMSD prevention, but are often overlooked.

Psychosocial aspects of the environment have the potential to influence stress processes, perceptions, emotions and behaviours. While organisational factors such as long working hours, stressful working conditions and workplace culture can all contribute to the injury mechanism.

2. Align individual factors and workplace factors

To mitigate injury risks it’s paramount we have a thorough understanding of the workplace factors that may increase the physical loads experienced by an individual.

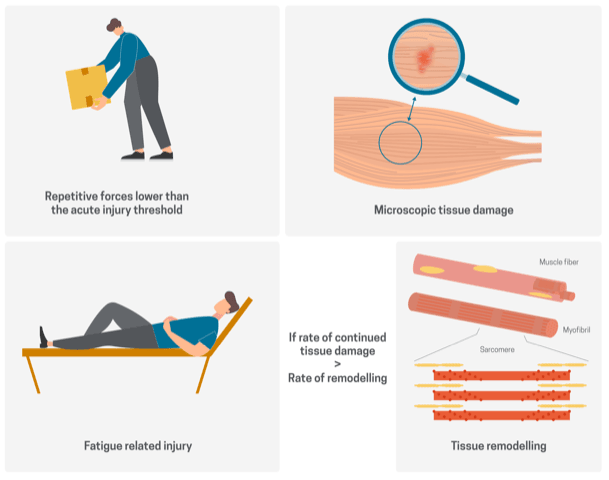

It’s also key we understand individual factors such as age, physical conditioning and potentially genetic predispositions. Having a mismatch between individual factors and workplace factors can create repetitive forces that are lower than the acute injury threshold of any given tissue.

When we continue to perform these repeated load scenarios at a rate greater than the capacity to remodel the tissue damage, we produce a combined fatigue effect in the tissue.

Over a period of time, this will lead to a musculoskeletal injury. If not managed appropriately, we create a cycle within the individual, which causes discomfort, pain, inflammation and eventually a musculoskeletal disorder.

3. Understand biomechanics

Biomechanics can help optimise design, products, or work processes by analysing the way people interact with their environment.

To achieve this, we must understand the postures and movements undertaken by the worker. Once this is understood, the goal of this should be to reduce human error, and improve the worker’s productivity, safety, and comfort.

This has the potential to help companies and their employees undertake work activities while improving performance and reducing the risk of WMSD.

4. Capture data

Biomechanic data can open an organisation’s eyes to the risks their workers are under. Having the appropriate measurement technologies allow us to observe the characteristics of movement, which enables sufficient evaluation or diagnosis against what is healthy. For example, we use a motion tracking Xsens suit in our Alter Ergo product to gather data around joint angles and postures.

Once we have established these factors, we have the potential to design appropriate interventions.

5. Create interventions

Interventions can take on many formats. From educating individuals on appropriate lifting techniques, to physical conditioning factors such as strength, endurance and flexibility, to task specific interventions such as technique training.

Interventions may also involve task specific and equipment factors, such as the engineering of new tools and processes.

6. Refine work factors

Finally, overall workplace organisation and job design factors can be taken into consideration, including the length of shifts, appropriate breaks, and the rotation of stations at different stages of assembly in plants and manufacturing factories.

Work-related musculoskeletal disorders are a substantial and ongoing problem in industry. Significant changes in practises are required to address the problem, but a holistic approach is key to reducing the risk. It’s time we applied a fresh approach to an age-old problem.

Written by Principia Technology Founder Dr Jason Konrath. Jason is a former IFBB Australian bodybuilding champion, holds a PhD in Biomechanics and a degree in Exercise and Health Science. He has an extensive background in both research and fitness coaching in a variety of elite sports from all over the world.